What You Need to Know About Measurement Uncertainty in 2024: A Simple Explanation

Every measurement is subject to uncertainty. Various factors, such as the measurement instrument, the object being measured, the environment, and the operator, can contribute to the measurement uncertainties. Such uncertainties can be estimated using statistical analysis of a set of measurements and other relevant information.

This article aims to demystify measurement uncertainty, making it understandable for people who know little about it, but need to learn about it.

01 What is Uncertainty of Measurement

In metrology, measurement uncertainty is the expression of the statistical dispersion of the values attributed to a measured quantity. Simply put, we express the uncertainty as a range within which we believe the true value is likely to lie.

For instance, if you're measuring the length of a piece of paper with a ruler, the actual length may be 10 mm. However, due to the limitations of the ruler's accuracy, your measurement might be 9.8 mm or 10.2 mm instead of the exact 10 mm.

In this example, the uncertainty in measurement arises from factors such as the precision of the ruler and your visual estimation abilities. Therefore, we cannot simply state that the length of this paper is 10 mm. Instead, we need to include an uncertainty, for example, (10±0.2) mm, indicating that the measurement result falls within the range of 10 mm with a margin of ±0.2 mm.

Measurement uncertainty serves as a vital indicator, giving us insights into the reliability and accuracy of our measurement results and helping us interpret experimental or measurement data.

02 How to Express Measurement Uncertainty

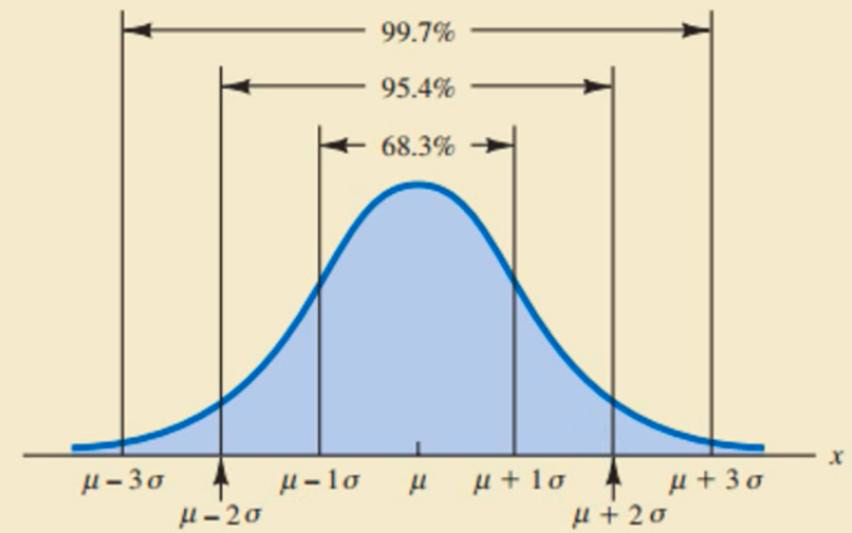

Quantifying uncertainty involves two key elements: defining the range of error, representing the upper and lower limits of measurement results, and establishing the confidence probability, indicating how confident we are that the "true value" falls within this range.

Usually, we employ a range with a coverage factor of k=2 to estimate the overall measurement error, providing an approximate 95% confidence level. This approach allows us to describe the uncertainty of measurement results with minimal error range and a high level of confidence, aiding in a better understanding of measurement outcomes and assessing their reliability.

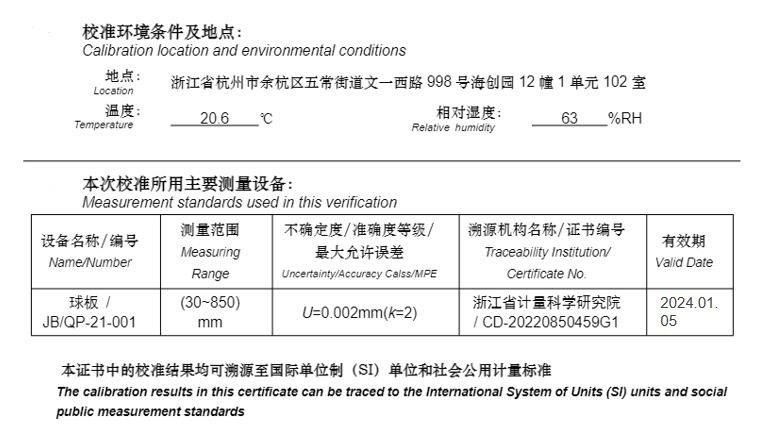

The Scantech Calibration Center has obtained ISO 17025:2017 and CNAS accreditation, which are globally recognized standards for quality management in testing and calibration laboratories. This signifies that Scantech has the technical capability to conduct traceable metrological calibrations in the field of optical 3D measurement systems in accordance with international standards.

Below are the certificate for the 3D scanner obtained after calibration at the Scantech Calibration Center. The 3D scanner conducted numerous repeated measurements on the sphere artifact. Additionally, we factored in details like the certificate of the sphere artifact and calibration environmental conditions. The resulting expanded uncertainty was calculated as U=0.010 mm, considering a coverage factor of k=2.

03 What are the Factors Influencing Measurement Uncertainty?

During the measurement process, several factors can contribute to the increase in measurement uncertainty. Firstly, there is the measurement capability of the instrument itself regarding the object, including factors such as resolution, accuracy, stability, and calibration status. Secondly, environmental factors such as temperature, humidity, and noise variations can impact measurement results. Lastly, human factors, such as operator skills and limitations in visual judgment, can introduce errors into the measurement results.

04 How to Reduce Measurement Uncertainty

While complete elimination of measurement uncertainty is impossible, there are methods to minimize it:

Appropriate Measurement Methodology: Choose suitable instruments and methods tailored to different measurement purposes and the characteristics of the measured object.

Instrument Calibration and Maintenance: Regularly calibrate and maintain equipment to ensure optimal performance.

Effective Software Utilization: Use high-quality data processing and analysis software to minimize errors in data processing.

Skill Enhancement: Train operators to enhance their skills and experience, reducing human errors in operations.

Environmental Control: Manage the measurement environment, including humidity and temperature, to prevent environmental factors from affecting results.

05 Reduce Measurement Uncertainty with the Scantech’s 3D Scanner

Scantech's 3D scanner excels in minimizing measurement uncertainty through its robust performance:

High Precision and Resolution: Providing high-resolution and accurate data to capture small details, minimizing result errors.

Non-contact Measurement: Utilizing non-contact measurement methods to prevent errors from physical contact with easily damaged or complex surfaces.

Quick Data Acquisition: Swiftly obtaining data on the measured object's surface, enhancing efficiency and reducing potential errors.

Advanced Data Processing: Equipped with advanced data processing software for automated data analysis, minimizing uncertainty arising from manual processing.

Flexibility and Adaptability: Exhibiting strong material adaptability and flexibility to measure objects of various sizes and materials.

In conclusion, measurement uncertainty, a quantitative indicator for accuracy, underscores the importance of understanding and addressing potential errors in measurement results. Employing appropriate instruments, considering environmental conditions, and refining operational techniques contribute to ongoing efforts to reduce measurement uncertainty, ultimately enhancing measurement accuracy and result credibility.